CONTOUR CUTTING AND CUTTING TECHNOLOGY FILM

1. WHAT IS CONTOUR CUTTING?

Contour cutting – is the process of cutting out images, shapes or contours on vinyl film with high precision and detail. This method is widely used in the production of vinyl stickers and graphic elements such as logos, letters, images and other design elements. Contour cutting allows you to create stickers of different shapes and sizes, making it an indispensable tool for advertising, marketing and design.

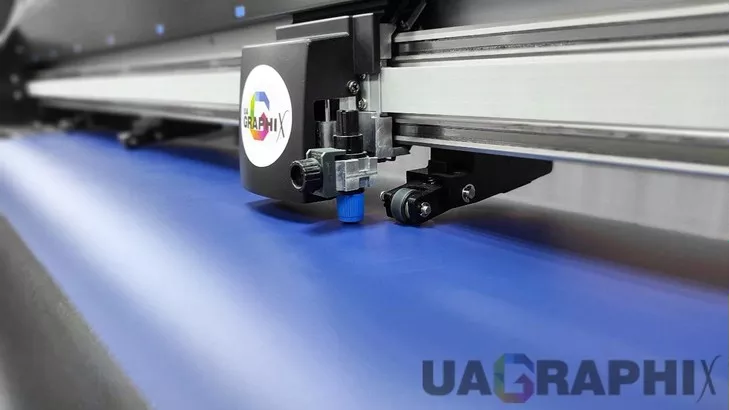

The contour cutting process is done using special equipment such as a cutting plotter or cutting machine. These are equipped with a sharp blade or cutting tool that follows the contours of the image given in the design file. It is important to note that contour cutting is not limited to straight lines or simple shapes. It is capable of cutting complex curves and details, making it a versatile method of creating various graphic elements.

So, contour cutting is a key step in creating vinyl stickers and graphic elements, allowing you to achieve high quality and individuality in production.

Benefits of contour cutting include:

- Multiple sizes available: Contour cutting allows you to create stickers and graphics in a variety of sizes, from small labels to large banners.

- High precision and detail: This method provides precise material processing, even the most intricate and minute details on the vinyl film.

- Custom Design: Contour cutting allows you to create unique designs, which is especially important for personalizing products and promotional materials.

- Simplicity and speed: The contour cutting process is automated, this speeds up production and ensures high work efficiency.

- Wide selection of materials: You can use different types of vinyl film, including different colors, textures and types, to create different graphic elements.

So, contour cutting is a key step in the creation of vinyl stickers and graphic elements, allowing you to achieve high quality and individuality in production.

2. PRODUCTION OF SINGLE COLOR STICKERS FROM uaGraphix

Manufacturing Process:

- Design preparation: At the beginning of the process, our customers choose a design that specifies the shape and size of the sticker. We work with different file formats, which makes the process convenient for our customers.

- Vinyl film selection: uaGraphix provides a wide range of vinyl film in different colors and shades. This allows our customers to choose the film that perfectly suits their design and color palette.

- Loading the large-format cutting machine with the selected material: We use state-of-the-art equipment, including cutting plotters, for high-precision sticker cutting. The design is loaded into the plotter, which automatically cuts the sticker according to the specified parameters. Then our specialists carefully process the cut design so as not to damage the product and not to leave any stains or unpleasant fingerprints. All works are carried out with special gloves on their hands.

- Quality Control: uaGraphix pays special attention to quality control. We check every sticker for defects and cut accuracy to make sure it meets our high standards.

- Personalized approach: We are ready to work on projects of varying complexity and size, from small stickers to large graphics.

- Duration: Our stickers are made from high quality vinyl film that has excellent resistance to external influences such as moisture, UV and wear and tear.

- Branding: Simple one-color stickers from uaGraphix are ideal for branding products, packaging and other items, making them an effective marketing tool.

- Fast order fulfillment: We strive to fulfill orders quickly and efficiently, which is important to our customers.

3. PRODUCTION OF FULL COLOR STICKERS FROM uaGraphix

After printing, the finished design is loaded onto our large format cutting plotter to further apply the cut line to the image along the contour. This process is performed with high precision, ensuring excellent quality full-color stickers.

The process of applying the cut line after printing:

- Material alignment: The material is initially aligned using optical positioning based on a laser level. This allows precise synchronization of the special marks that are applied to the edges of the printed design during printing.

- Scanning the material: The material is then scanned to determine possible misalignment. This ensures that the material is correctly positioned inside the plotter and is ready for accurate and even application of the cut line.

- Mark Scanning: The cutting plotter scans special marks located at the edges of the printed design. This allows you to determine the exact coordinates of the contour cut. The process is fully automated and eliminates possible inaccuracies resulting from scanning or other errors caused by human error.

- Applying the cut line: After scanning the marks, the contour cutting process begins. Our plotters work with great speed and precision to create a precise and professional contour cut, respecting the given coordinates.

4. OUR BENEFITS:

- High precision and detail: We only use professional equipment known for its unique ability to deliver high precision work. This makes it ideal for creating intricate and minute designs such as fine fonts or intricate patterns.

- A wide range of compatible materials: Compatible with a variety of materials, including different types of vinyl film, paper of different weights, cardboard and other materials. This provides flexibility in material selection for different projects.

- Automatic label alignment and scanning: Our plotter is equipped with an automatic material alignment function using optical positioning and mark scanning. This ensures that the material is accurate and correctly positioned before starting work.

- Speed and performance: We offer a high speed of operation, which allows us to fulfill orders quickly and reduce waiting times.

5. PORTFOLIO:

We believe that visual examples will help you better appreciate our capabilities and inspire you to create your own projects. Browse our works and find inspiration for future orders together with uaGraphix.

6. COLOR PRINTING:

More about our color printing production and technology you can learn on this page Printing and HP Latex Eco-Friendly Ink Technology

7. CONTACT US:

We are ready to help you turn your ideas and projects into reality. If you have any questions, want to learn more about our services or place an order, just contact us. uaGraphix is a friendly and professional team ready to answer your inquiries and provide you with the information you need.